Flame polishing acrylic edges machine polishes the edge of acrylic products, and the acrylic burrs after flame high temperature polishing, the plexiglass/perspex becomes clear and translucent. The flame polishing machine has a high temperature, which is especially suitable for the rapid transparent polishing of plexiglass processing, acrylic product polishing, concave surfaces, and equilateral corners of advertising crystal characters or handicraft carvings. It is environmentally friendly and economical.

Polishing Acrylic Edges Operation Video

The principle of the flame polishing acrylic edges machine is a new type of new energy equipment that uses the technology of electrolysis of water to produce hydrogen and oxygen gas from the water after being energized. Hydrogen is used as a fuel for combustion, and oxygen is used as a combustion aid to support combustion, replacing various carbon-containing gases such as acetylene, coal gas, and liquefied gas. The hydrogen-oxygen flame has the characteristics of high calorific value, concentrated flame, no carbon, no emission, high production efficiency, high efficiency and environmental protection.

Polishing Acrylic Edges Machine Packing list

- main set,

- flame torch

- hose

- powder

- manual book

- funnel

- All packed in strong canton with foam

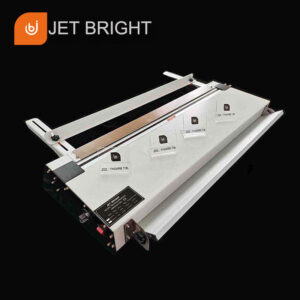

Polising Acrylic Edges Machine Product Detail

HD display ammeter

304 stainless steel voltmeter

Accurate display of water meter

The small horse chestnut fan powerfully cools down and works continuously, keeping silent

Bold and enlarge the transformer, could use for long time. And make working safe.

Flame Polishing Acrylic Edges Machine Detail

max. gas production: 95L/H

voltage : AC220V 1. 5A/AC110V3.1A

water consumes: 30 mL/H

max.water adding : 1. 0 L

solution density : 15%

pressure range: 0.13-0.15Mpa

weight: 8 kg

size: 480*280*360 mm

Flame Polishing Acrylic Edges Application

Quick polishing of acrylic products with various thicknesses, such as rough sides, concave surfaces, inner holes, curved sides, and other special-shaped edges and corners-solve the problem that ordinary polishing machines can’t do, and it is environmentally friendly and economical.

1). Property indication signs: organic glass decorations, crystal characters, property signs, listings, image signs, light boxes, (used in hotels, office buildings, commercial houses, etc.).

2) Electronics (IT) category: mobile phone racks, USB disk racks, MP3/MP4 display racks, VCD display racks, digital camera racks, laptop display racks, remote control ornaments, battery boxes, computer cases, plexiglass speakers, digital display racks, electronics Rotating showcase, etc.

3) Tobacco wines: acrylic cigarette holders, cigarette cases, wine holders, wine boxes, liquor licenses, desk cards, etc.

4) Stationery category: perspex document holder, pen holder, stationery holder with business card holder, Expo souvenirs

Wait.

5) Women’s products: acrylic frame, jewelry box, acrylic cover, etc.

6) Other supplies: plexiglass photo holder, plexiglass fish tank, plexiglass medicine box, acrylic glass shoe rack, pmma paperweight, plastic tissue box, plexiglass boutique box, plexiglass work number plate, plexiglass distribution card.

7) Crystal crafts: acrylic glass crystal trophy, perspex crystal model, plexiglass crystal inner carving, plexiglass crystal doll.

8) Crystal glue products: acrylic glue hourglass, plexiglass genuine product built-in, plexiglass crystal glue ashtray

9) construction: architectural lighting, transparent roof, roof, telephone booth, stairs and room wall guards, etc.

10) Sanitary ware: bathtub, washbasin, dressing table and other products.

Advantages of frame polishing acrylic edges ?

- The flame polishing machine is produced on demand without storage. Compared with high-pressure gas cylinders, it is safe and convenient.

- The principle of the flame polishing machine is simple, it only needs water and electricity, and it is ready to use when it is turned on. It is economical and applicable, has good mobility, and is small. It is suitable for the requirements of a variety of working conditions.

- The flame of the flame polishing machine is concentrated, which is suitable for precision flame processing and has high processing efficiency.

- The hydrogen and oxygen produced by the flame polishing machine are odorless and non-toxic, and the combustion product is only water, which does not pollute the environment.

- The hydrogen-oxygen flame of the flame polishing machine is a carbon-free flame, which will not cause secondary damage to the workpiece, and the workpiece is welded and fastened without carbon embrittlement.

- Safe anti-tempering device, long-life electrolytic cell and easy-to-use hydrogen-oxygen flame gun ensure convenient operation, durability, safety and efficiency